Elevating Performance: The Power of Polyurethane Elastomers in Industry

In the world of industrial materials, few substances boast the versatility and resilience of polyurethane elastomers. These dynamic compounds have revolutionized a multitude of industries, offering unmatched durability, wear resistance, and customization options. From manufacturing and automotive to aerospace and beyond, polyurethane elastomers have become the go-to solution for demanding applications. Join us on a journey to uncover the incredible capabilities and diverse applications of this remarkable material, and discover why it's transforming the way industries operate.

Understanding the Versatility and Strength of Polyurethane

Polyurethane elastomers, often referred to simply as "PU elastomers," represent a class of polymers celebrated for their remarkable versatility and exceptional strength. Formulated through a unique chemical synthesis, these elastomers exhibit a wide range of mechanical properties, making them suitable for a diverse array of applications. Their inherent flexibility, combined with an impressive load-bearing capacity, sets them apart as a formidable material in the industrial landscape.

Why Polyurethane Elastomers Stand Out in Industrial Applications

Polyurethane elastomers have earned their place as a cornerstone in various industrial sectors for several compelling reasons. Their resistance to abrasion, impact, and wear surpasses that of many traditional materials. This, coupled with their ability to endure harsh environmental conditions, positions them as a top choice for components subjected to demanding operational challenges. Additionally, their customizable formulations allow for tailoring properties to specific requirements, offering an unparalleled degree of adaptability in engineering solutions.

In the realm of industrial applications, few materials rival the sheer resilience and adaptability of polyurethane elastomers. Their unique combination of properties makes them a cornerstone in industries ranging from manufacturing and automotive to aerospace and beyond. Let's delve deeper into the myriad ways in which these exceptional elastomers are reshaping the landscape of industrial materials.

In the realm of industrial applications, few materials rival the sheer resilience and adaptability of polyurethane elastomers. Their unique combination of properties makes them a cornerstone in industries ranging from manufacturing and automotive to aerospace and beyond. Let's delve deeper into the myriad ways in which these exceptional elastomers are reshaping the landscape of industrial materials.

Types of Polyurethane Elastomers

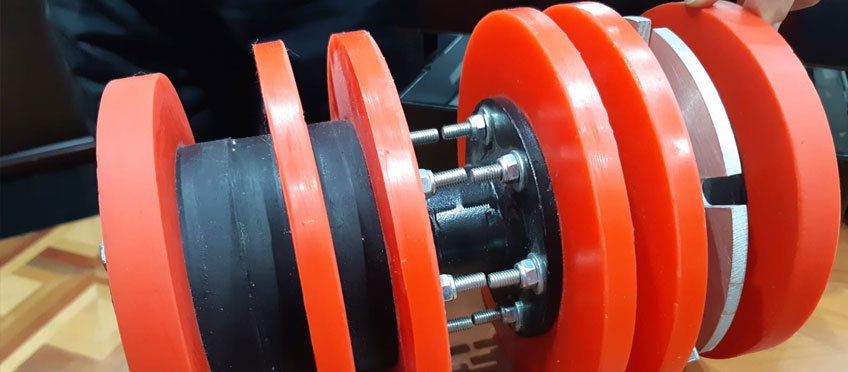

- Polyurethane Bushing: Polyurethane bushings are versatile components known for their excellent load-bearing capabilities and resistance to wear and tear. They find widespread use in various industrial applications, providing stability and vibration isolation.

- PU Buffer: PU buffers, or polyurethane buffers, are engineered to absorb and dissipate energy, making them invaluable in applications where shock absorption and noise reduction are critical. They are widely employed in industries such as automotive and manufacturing.

Both Polyurethane Bushings and PU Buffers are crucial components known for their durability and resilience, contributing to the efficiency and reliability of machinery and equipment in diverse industrial settings.

Applications of Polyurethane Elastomers Across Industries

Here are the applications of Polyurethane Elastomers across various industries:

Polyurethane elastomers are a versatile material that finds wide-ranging applications in industries that demand durability, resilience, and performance under challenging conditions. Their use in manufacturing, automotive, construction, marine, aerospace, and defense industries underscores their significance in advancing technology and infrastructure.

- Manufacturing and Industrial Equipment: Polyurethane elastomers play a vital role in manufacturing and industrial settings. They are used in components like seals, gaskets, rollers, and machine parts to enhance wear resistance, reduce noise, and improve overall equipment performance.

- Automotive and Transportation: In the automotive and transportation industry, polyurethane elastomers are employed in suspension systems, bushings, engine mounts, and various other components. Their durability, resilience, and vibration-dampening properties make them indispensable for vehicle performance and longevity.

- Construction and Infrastructure: Polyurethane elastomers find extensive use in construction applications. They are utilized in items such as concrete molds, bridge bearings, and various structural components. Their ability to withstand heavy loads and harsh environmental conditions is crucial in construction projects.

- Marine and Offshore Engineering: In marine and offshore engineering, where equipment is exposed to corrosive saltwater and harsh conditions, polyurethane elastomers are used in components like marine fenders, underwater seals, and offshore pipeline coatings. Their resistance to abrasion and chemicals makes them ideal for marine applications.

- Aerospace and Defense: Aerospace and defense industries rely on polyurethane elastomers for critical applications such as aircraft seals, vibration isolators, and missile components. Their lightweight yet durable nature, along with their ability to withstand extreme conditions, makes them a preferred material in these sectors.

Polyurethane elastomers are a versatile material that finds wide-ranging applications in industries that demand durability, resilience, and performance under challenging conditions. Their use in manufacturing, automotive, construction, marine, aerospace, and defense industries underscores their significance in advancing technology and infrastructure.

Selecting the Right Polyurethane Elastomer for Your Application

Factors to Consider:

- Load-Bearing Capacity: Evaluate the expected load or stress that the Polyurethane Elastomer will be subjected to. This factor is crucial in ensuring that the chosen elastomer can withstand the specific forces it will encounter in the application.

- Environmental Conditions: Take into account the environmental factors the elastomer will be exposed to. Consider aspects such as temperature variations, exposure to UV radiation, moisture levels, and potential exposure to chemicals or corrosive substances.

Expert Tips for Optimal Material Selection

- Consult with Manufacturers or Suppliers: Seek advice from experienced manufacturers or suppliers of Polyurethane Elastomers. They possess in-depth knowledge about various formulations and can provide valuable insights into selecting the most suitable material for specific applications.

- Consider Custom Formulations: In cases where standard formulations may not fully meet the application requirements, consider exploring custom formulations. Manufacturers can often tailor elastomers to meet specific needs, providing an optimal solution.

- Prioritize Longevity and Performance: Emphasize durability and performance when making a selection. Choosing a Polyurethane Elastomer that can withstand the demands of the application ensures longevity and reliable operation.

By carefully considering these factors and seeking expert advice when needed, you can make informed decisions when selecting Polyurethane Elastomers for your specific application, ultimately contributing to optimal performance and longevity of the components.

Where to Buy High-Quality Polyurethane Elastomer

As an ISO 9001:2015 certified company, Trinity Auto Engineering (P) Ltd. stands as a trusted and reputable manufacturer, supplier, and exporter of Polyurethane Elastomers in India. With a commitment to quality, we have earned a celebrated position in the industry. Our product range includes a diverse selection of Automotive Shock Absorber Bushings, designed to meet the needs of clients nationwide.

For those seeking top-notch Polyurethane Elastomers, TRINITY AUTO ENGINEERING offers the best quality options at competitive prices. Our range of Polyurethane Elastomers comes in various dimensions and specifications, ensuring versatility for different applications. Additionally, we provide customization options to meet specific requirements.

When it comes to high-quality Polyurethane Elastomers, TRINITY AUTO ENGINEERING is the go-to destination, known for delivering products of exceptional quality and reliability. Get In Touch!

For those seeking top-notch Polyurethane Elastomers, TRINITY AUTO ENGINEERING offers the best quality options at competitive prices. Our range of Polyurethane Elastomers comes in various dimensions and specifications, ensuring versatility for different applications. Additionally, we provide customization options to meet specific requirements.

When it comes to high-quality Polyurethane Elastomers, TRINITY AUTO ENGINEERING is the go-to destination, known for delivering products of exceptional quality and reliability. Get In Touch!